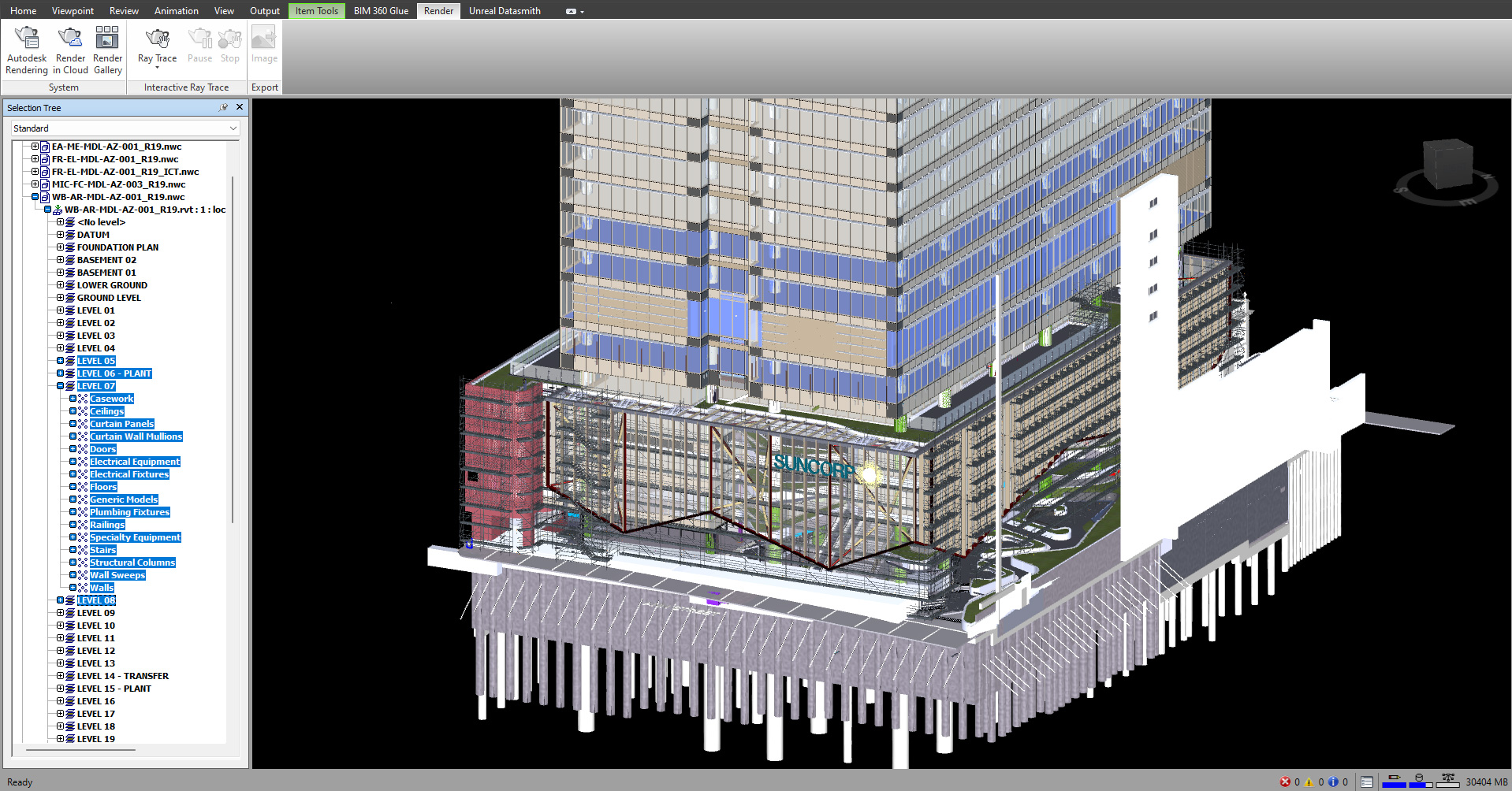

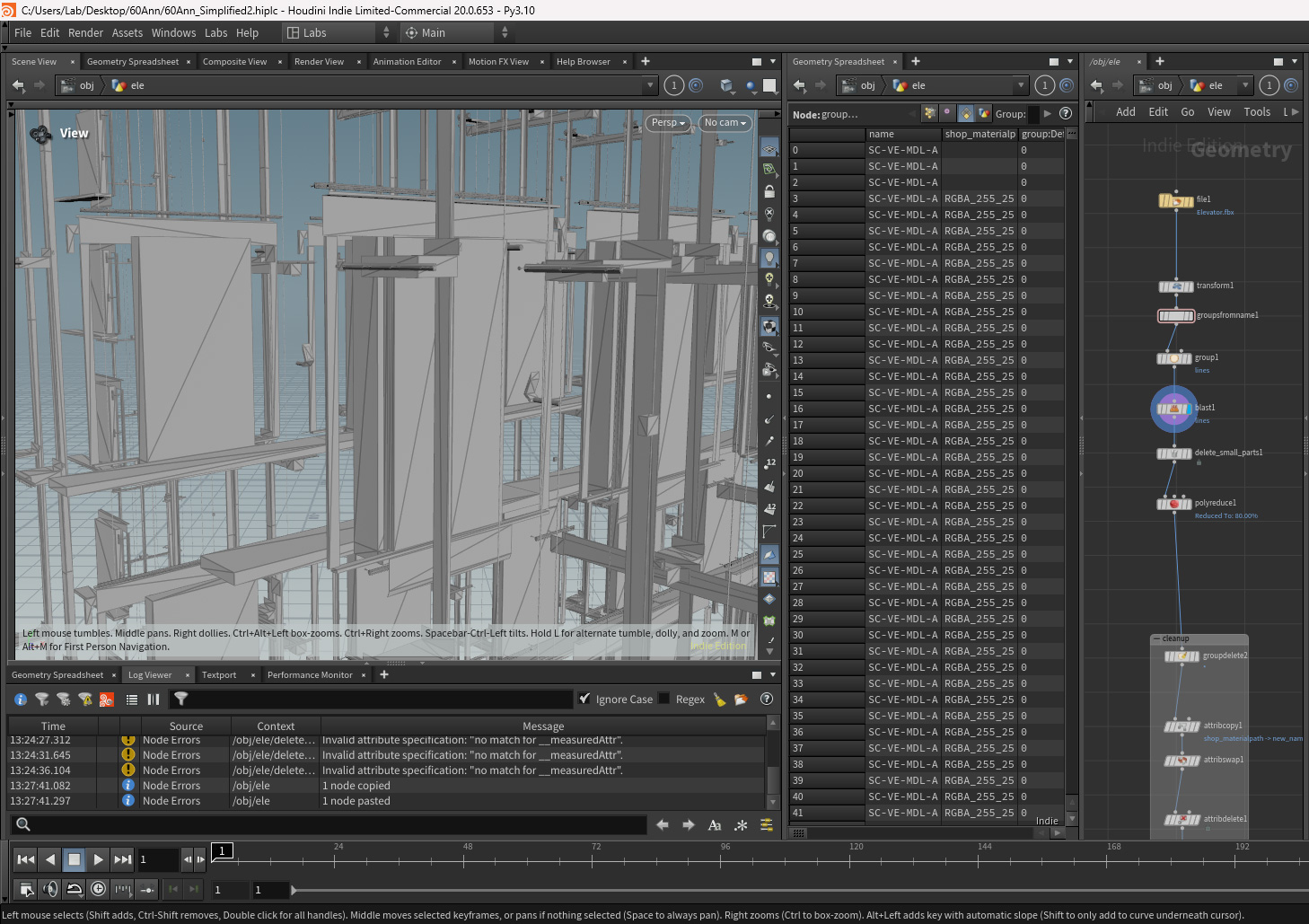

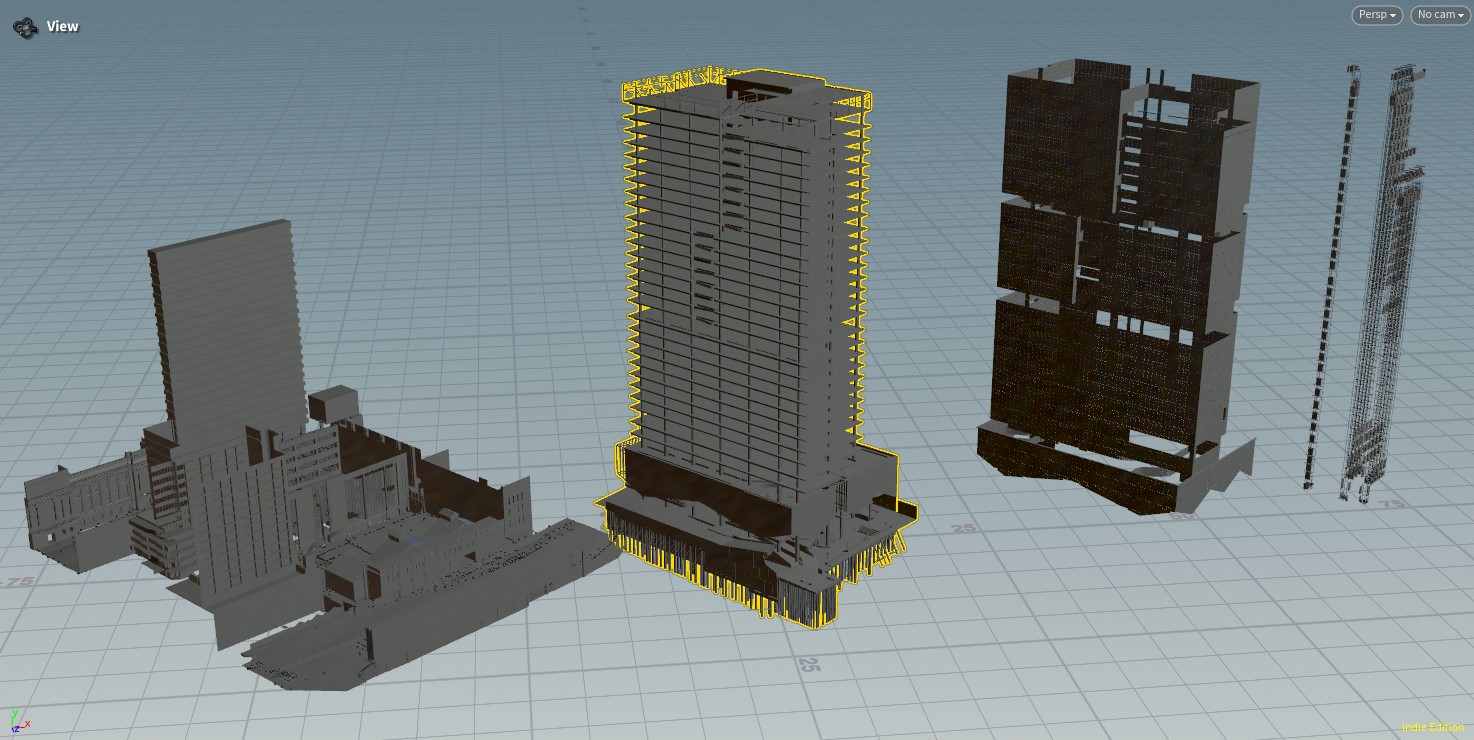

Big BIM data handling

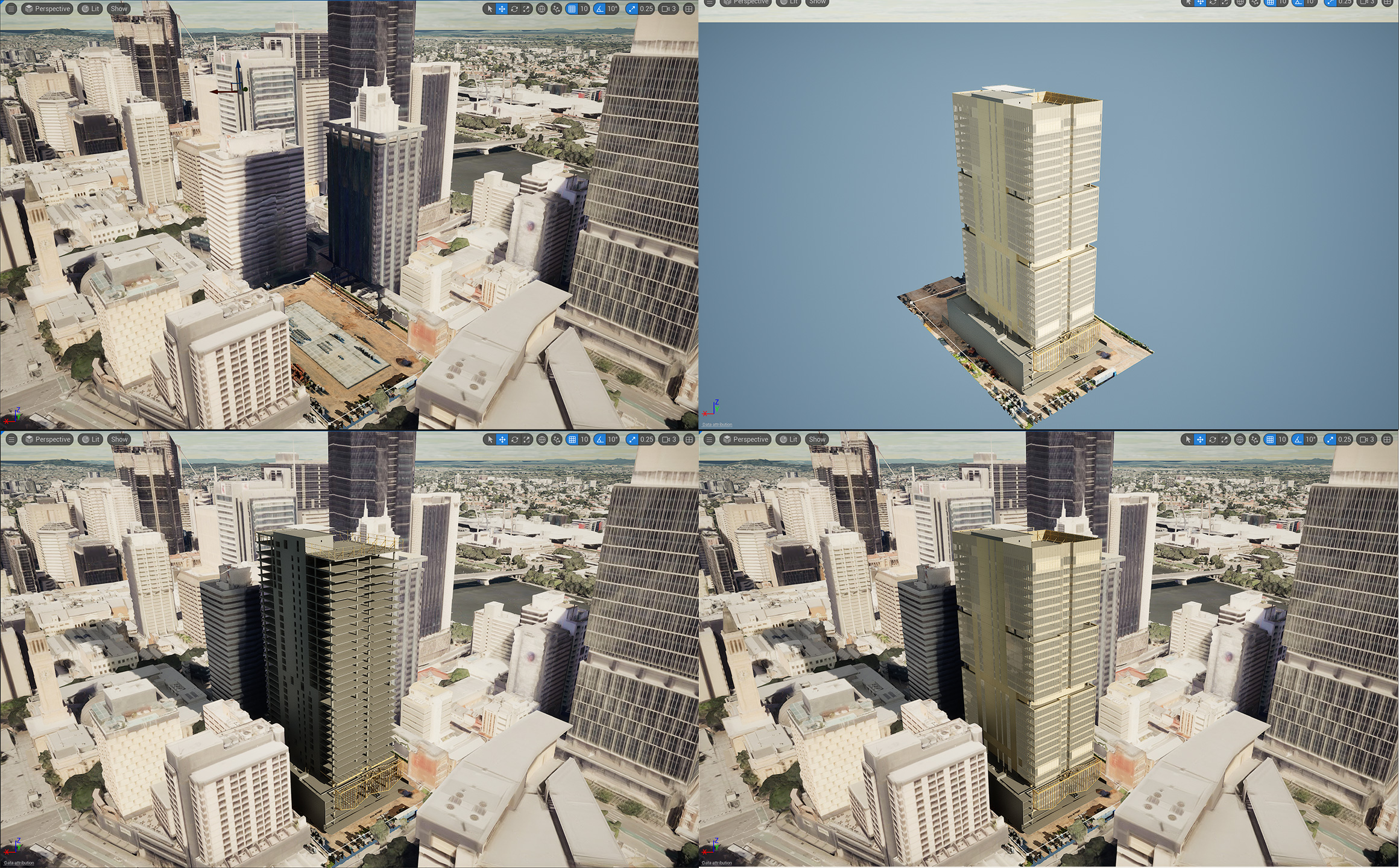

Using a BIM model of 80 Ann street, Brisbane, which contained all electrical, fire services and elevator details, I was able to segment and bring the CAD model into Houdini for poly reduction, UV cleanup and ultimately collapsing parts by material, so that the result could easily be brought into the Unreal engine for visualization (and VR!!!).

In the past, this process would usually take days of processing via multiple software packages, but with Houdini and a few attribute tricks, this only took a few hours. Import was painless!

I also leveraged the Cesium plugin to locate the building in Google 3D Maps Tiles for context. A week’s work in a matter of a day.

Stats

- 1.2 GB BIM model (19 embedded working files)

- 700k objects condenced down into 75 meshes with material data

- 32 million polys down to 4 million (unfortunately the fire service piping didn’t make the import due to too much detail)

- All processed on a laptop with 32GB of RAM (unheard of 5 years ago)

- Ceveat: Mesh only data, I’d need to impliment a Rhino/Grasshopper workflow for dealing with solids/surfaces

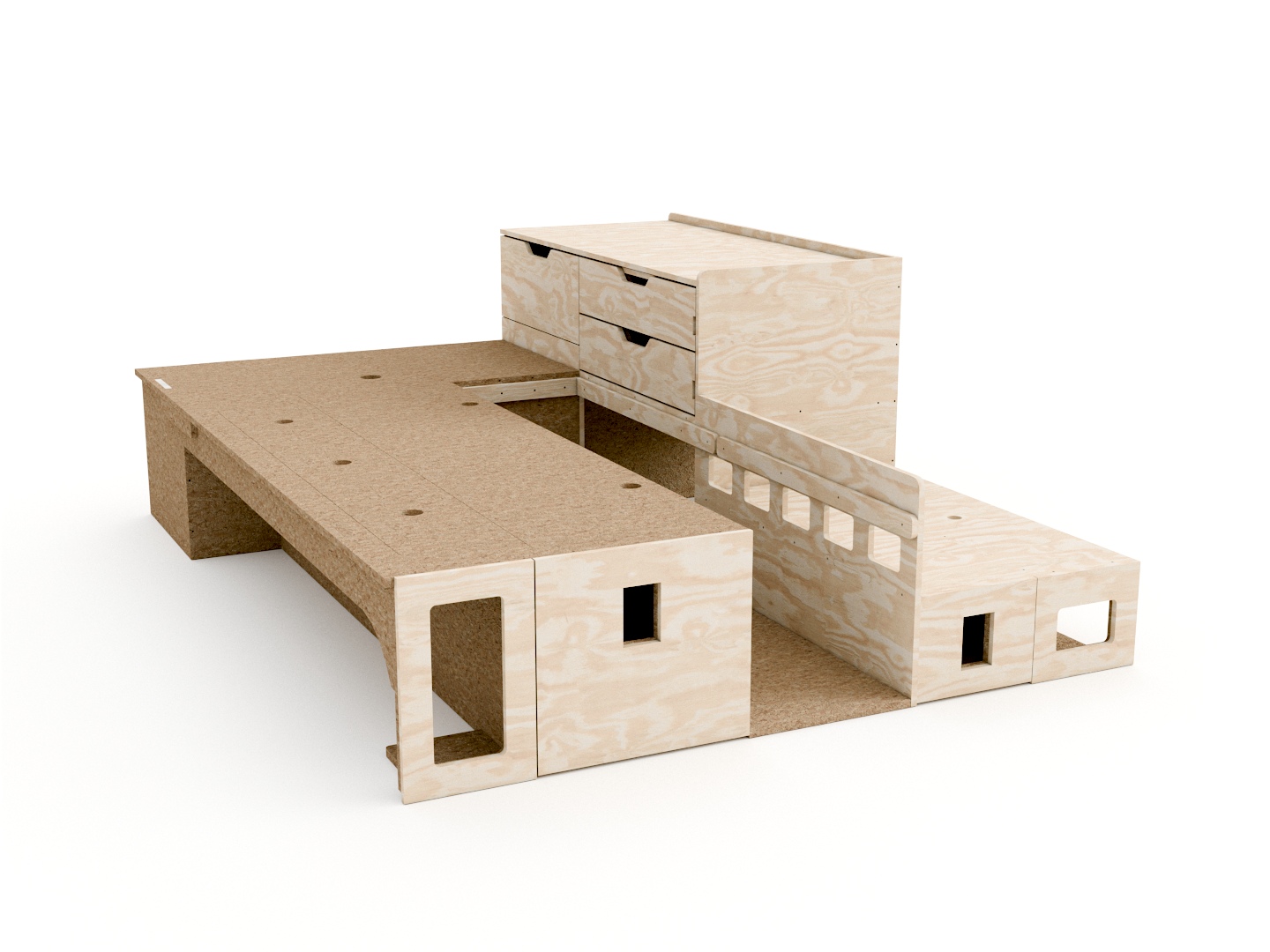

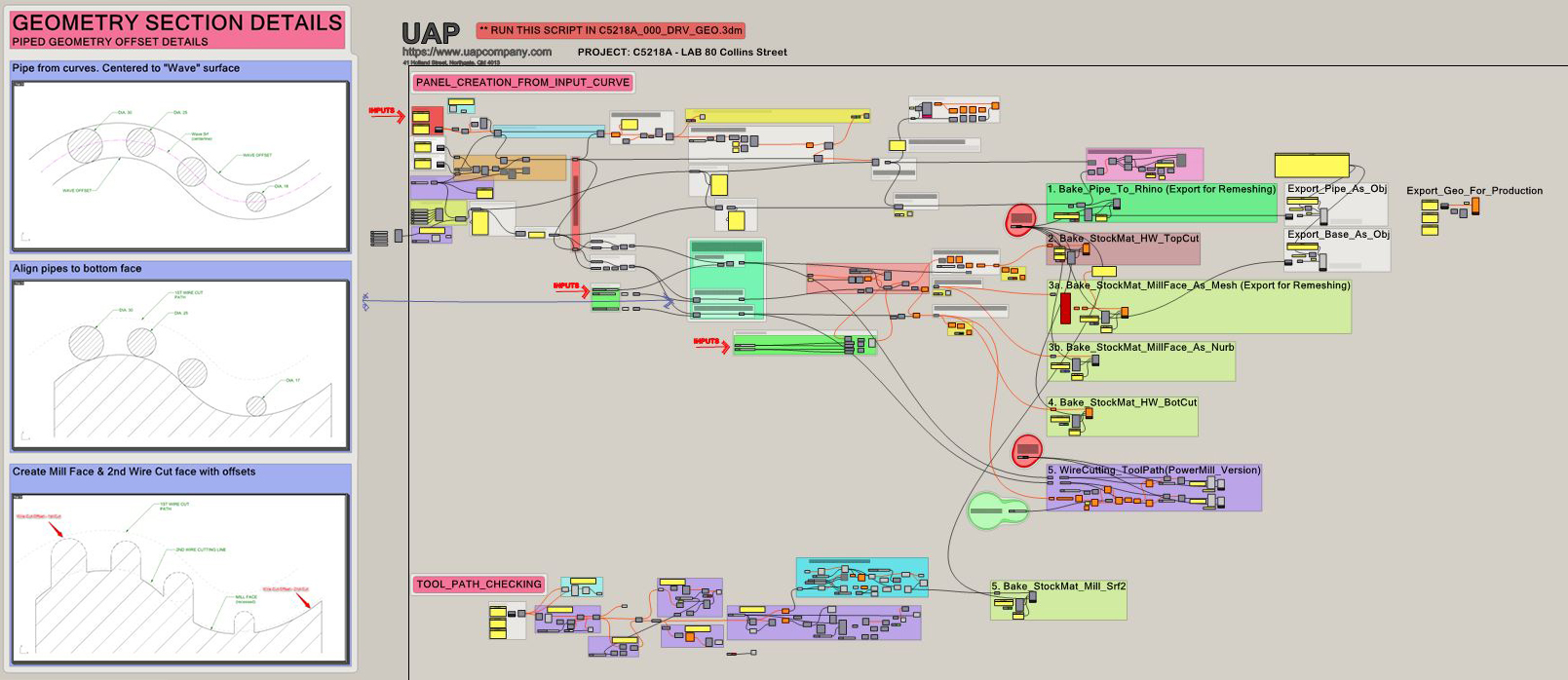

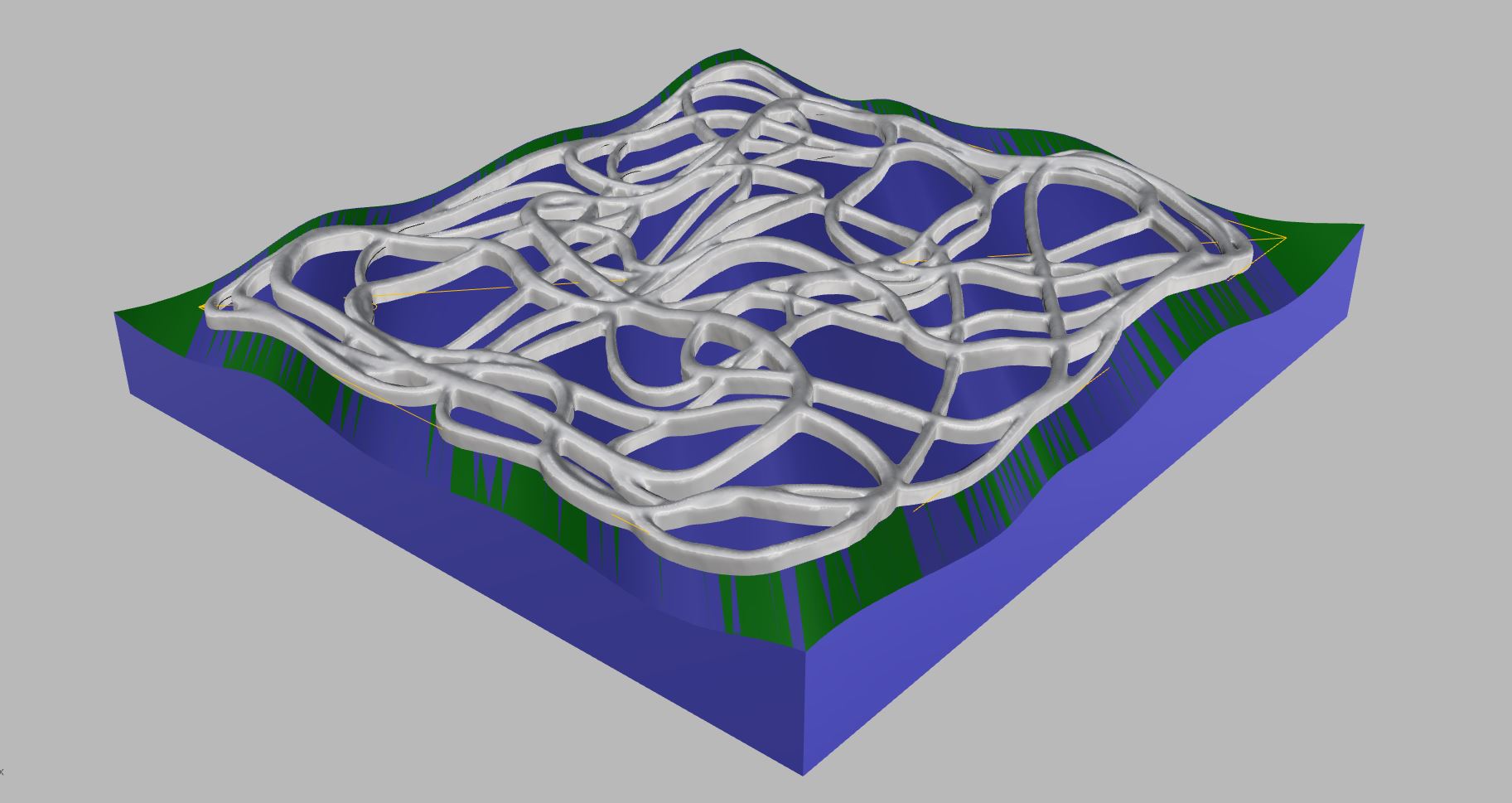

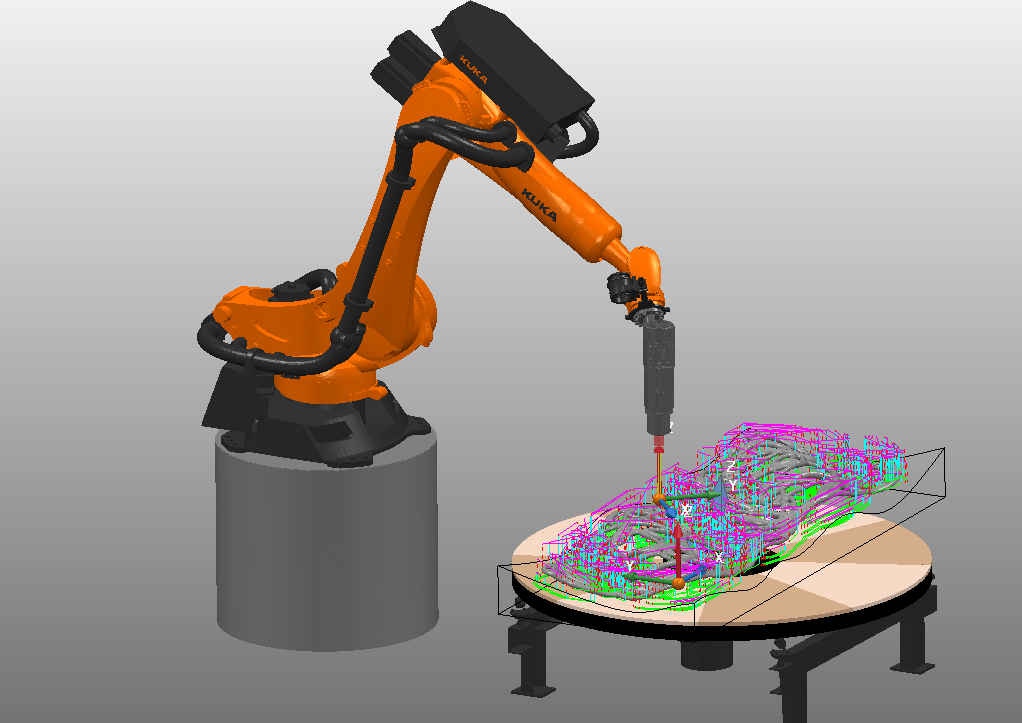

Procedural Design for Robots

Beyond design, I operated as a one-person technical team: developing the virtual production pipeline, programming the robot (learned in just one month), and managing milling operations. The result? A proof of concept demonstrating how parametric design and integrated workflows can deliver complex projects with unmatched efficiency—blending computational precision with hands-on fabrication expertise.

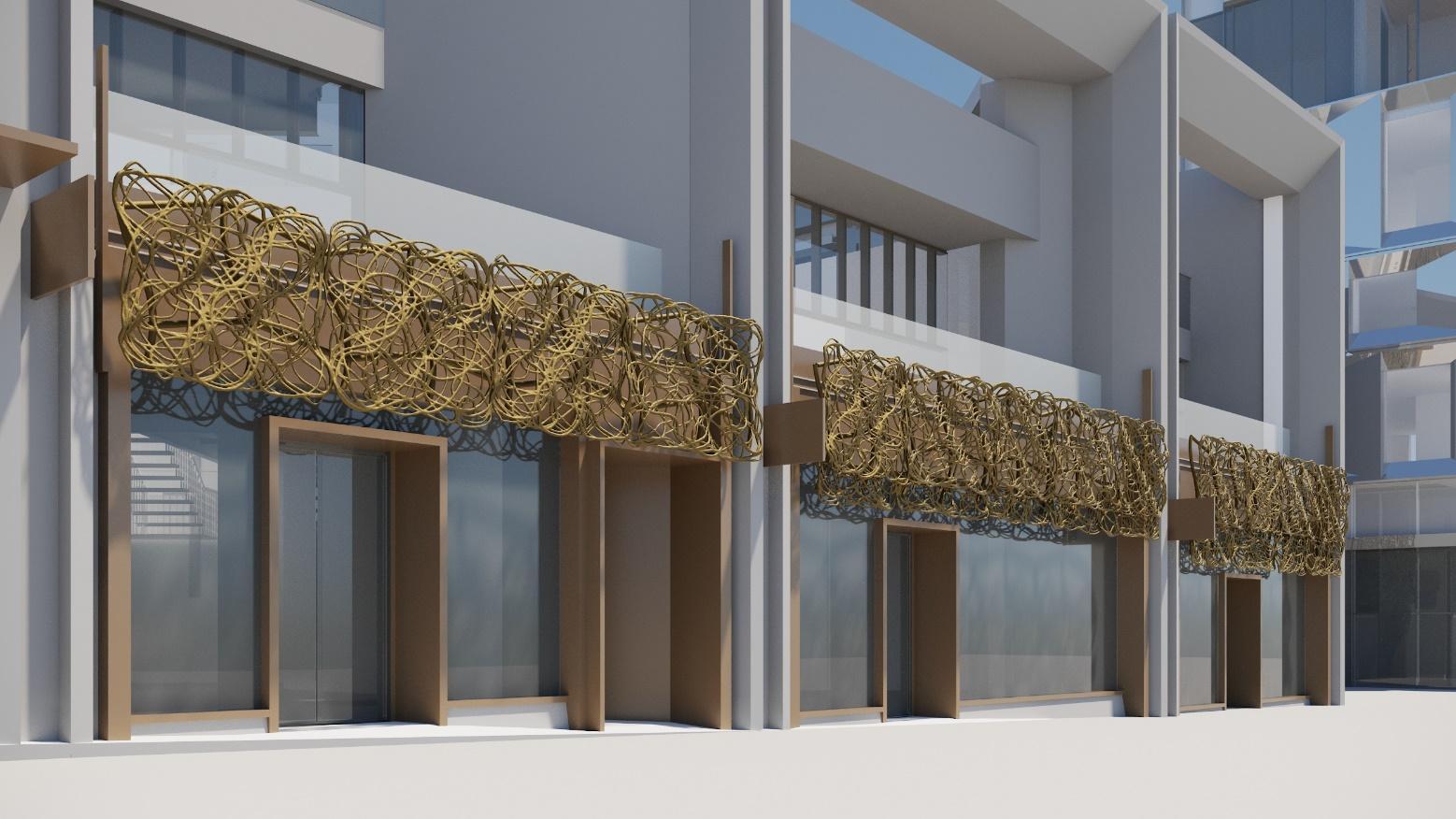

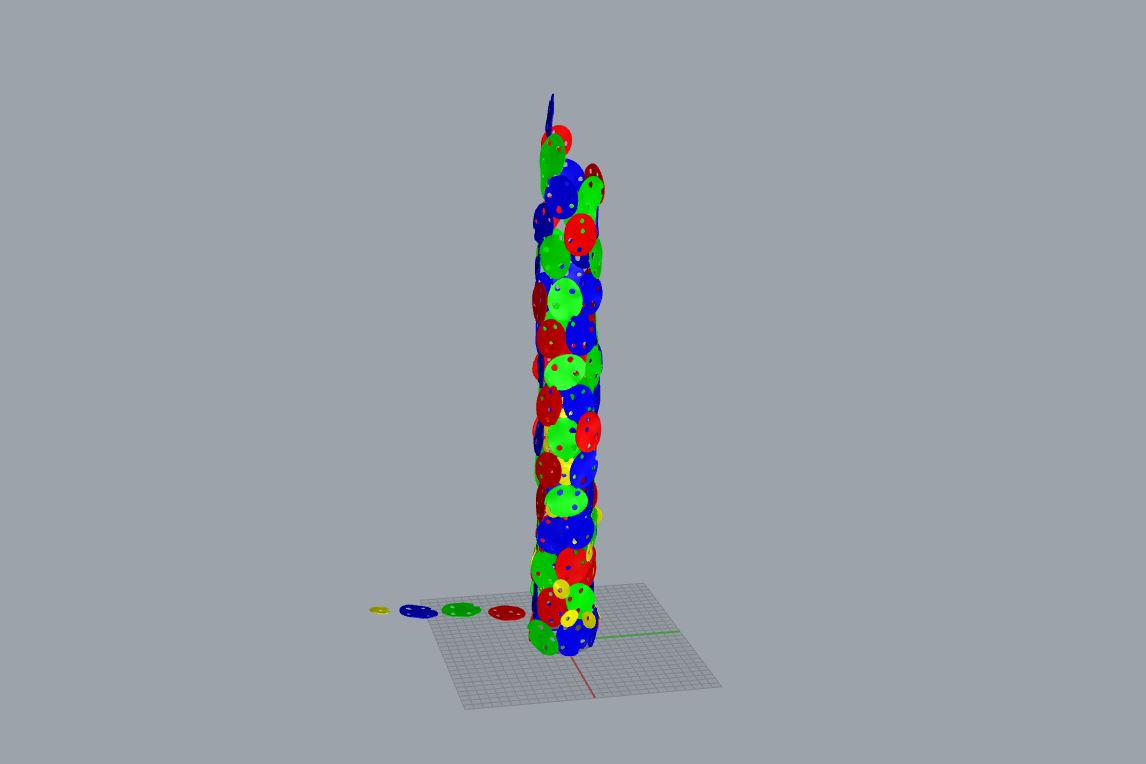

VR Design / AR Assembly

Katrina Tyler

’s "Flourish" sculpture became a pioneering case study in digital prototyping for fabrication, leveraging VR (Hololens) to streamline assembly under strict safety constraints (hand entrapment/climbability gaps).

Key Innovations:

Why It Worked: A perfect marriage of artistic complexity and industrial pragmatism—proving XR’s value in bridging design intent and physical execution.

(Future potential: Scaling AR workflows for large-team fabrication or modular construction.)

Project details

Design Robotics

UAP

Key Innovations:

- VR Spatial Planning: Replaced tedious on-screen placement with real-scale, immersive module arrangement.

- AR-Assisted Fabrication: Trained workshop staff to use Hololens for real-world assembly guidance and tack welding, reducing dependency on 2D drawings.

- Efficiency Gains: Eliminated hours of manual measurement checks, despite initial device troubleshooting.

Why It Worked: A perfect marriage of artistic complexity and industrial pragmatism—proving XR’s value in bridging design intent and physical execution.

(Future potential: Scaling AR workflows for large-team fabrication or modular construction.)

Project details

Design Robotics

UAP

Augement Assembly Fabrication (ARfab)

Precisely align a virtual CAD model (with 500+ unique rod locations and drill holes) to the physical structure for accurate tack welding – traditionally a drawing-intensive process prone to human error.

AR Solution:

- Successfully anchored the Hololens to the main structure (despite initial skepticism about tracking reliability)

- Enabled workshop teams to visualize and mark hole locations in AR, eliminating constant drawing references

- Completed the task faster than traditional methods, with superior accuracy

Impact:

- Significant labor hours saved in measurement and layout

- Demonstrated AR's potential to bridge digital design and physical fabrication

- First-hand validation of wearable AR's readiness for industrial workflows

When tracking works (sometimes miraculously), AR can outperform conventional methods – this project paved the way for more ambitious XR fabrication applications.

Project Details

Design Robotics

UAP

Interview

IndustrialViz

These pieces represent my specialized work in creating clear, informative visualizations of complex mechanical and architectural systems. As a visualization expert, I transform technical schematics into engaging animated explanations that reveal how machines function and modular construction systems assemble.

Product Visualization Expertise:

- Machine operation breakdowns with functional emphasis

- Modular construction sequencing for training/education

- Photoreal product demonstrations with technical accuracy

- Optimized animation pipelines for iterative updates

Whether explaining industrial equipment or building systems, my visualizations bridge the gap between engineering intent and audience comprehension. These projects demonstrate how strategic 3D animation can become a powerful tool for education, training, and technical marketing.